CSCE 436/836: Embedded Systems

Lab 1a: Hovercraft Construction and Experiments

Instructor: Carrick Detweiler

carrick _at_ cse.unl.edu

University of Nebraska-Lincoln

Spring 2011

Started: Jan 20, 2011

Lab 1 Due: Feb 3, 2011

Lab 1a Recommended Completion Date: Jan 27, 2011

1 Overview

This is the first part (a) of Lab 1. In this lab you will design,

construct, and perform experiments with the physical hovercraft. In

the second part (b) of this lab, you will learn to program the

hoverboard embedded system that we will use to control the hovercraft.

In future labs we will use the information you collect to calibrate

controllers you will develop on the hoverboard embedded system.

Before starting you should read through the whole lab. Some parts can

be done in parallel, while some sections rely on the completion of

previous sections. You should discuss your plan of attack for the lab

in your group and decide how you will work together and divide the

work. Everyone, however, is responsible for knowing about all

sections of the lab.

2 Materials

The main materials you will use in this part of the lab to construct

the hovercraft are:

- Sheet of 1.5 inch think rigid foam insulation

- 5mil plastic sheet

- Six GW/EDF40 Ducted Fans (thrusters)

- Wire, tape, brackets, screws, etc.

You will also use a various hand tools including knives, soldering

irons, power supplies, etc.

3 Safety

In this lab you will be using a number of tools and devices that can

be dangerous if mishandled. You should always follow instructions,

think twice, and ask for help if you are unsure what you are doing or

are unsure about safety. Please report any accidents to the course

staff and seek medical attention immediately if needed.

Reasonable precautions will prevent most accidents. Do not work in

the lab alone or when you are tired.

Throughout this course you will be using ducted fans for propulsion of

the hovercraft. These are relatively safe, but you should never put

your fingers or anything else inside of them. Along these lines, if

you have long hair, you should make sure to tie it back or cover it

while in the lab.

We will also be using power supplies and batteries in this course.

Make sure to follow instructions when using these devices as they can

be dangerous if misused. You should always be careful not to short

wires on batteries or power supplies and follow appropriate methods

for charging batteries.

Finally, in this lab you will be using sharp knives and soldering

irons. These can cut or burn you or your classmates. Always be aware

of your surroundings when using these devices and never cut towards

yourself or anyone else.

4 Hovercraft Design and Construction

In this section you will design and construct your hovercraft. The

exact configuration will be left up to you. The only constraint is

that the hovercraft must be omni-directional (able to translate in any

direction) and it must have rotational control (ideally equal control

clockwise and counterclockwise).

One of your goals in designing and constructing your hovercraft is to

make it look nicer than mine. This shouldn't be too hard :)

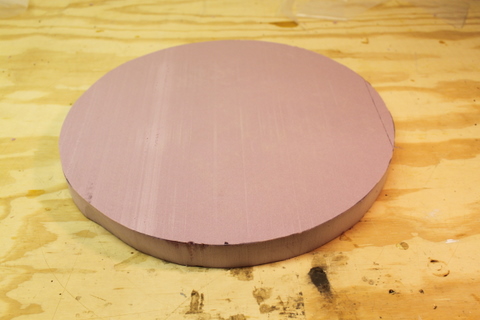

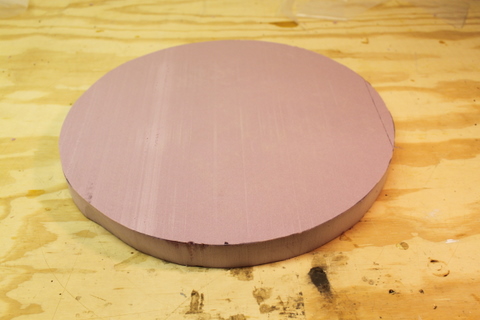

Figure 1: A foam circle cut out of the sheet of rigid foam.

For the base we will be using 1.5 inch rigid foam insulation. This is

a lightweight material that is easy to work with and relatively

inexpensive. There are a variety of circle templates that you can use

ranging from about 12 inches to 17 inches in diameter. You are free

to make your hovercraft whatever diameter you choose. The only

constraints are that it should be larger than 10 inches in diameter

and no more than 20 inches. You can also create other shapes,

although I suggest you cut a circle as it makes creating a good skirt

significantly easier.

To cut the foam, first lay your template circle on top of the foam.

Select a portion of the foam that will result in as little wasted foam

as possible. Trace a circle on the foam with a pen or marker. Remove

the template and then carefully cut the foam out using provided knife.

When using the knife extend the blade to a length slightly longer than

the width of the foam and then use the locking nut to lock the blade

in place. Make sure to keep the blade perpendicular the surface to

ensure a clean cut. Small sawing motions may be helpful. Note,

you should cut the foam over the plywood or off the edge of the

table so that you do not cut into the workbenches. Also, it may be

helpful to do a rough cut first (minimizing waste) so that you can

maneuver the piece of foam more easily.

Figure 1 shows the end result. Having a perfect

circle is not critical, but you should trim off any large errors. You

can always make a slightly smaller circle if you mess up the first

cut.

Question: What diameter hovercraft base did you decide to use? What was your reasoning?

Figure

Figure 2: A flexible walled skirt design. Air flows down into the skirt and inflates it. Most air remains inside and recirculates. A small amount of air leaks out and provides the air cushion (Image modified from original on wikipedia.org hovercraft entry).

The skirt is the most critical component of a hovercraft. There are

multiple types of skirts including bag skirts, wall skirts, and finger

skirts (roughly ranging from easiest to hardest to build). The goal

of all skirt designs is to provide a small cushion of air under the

hovercraft, while adapting and conforming to any irregularities in the

surface. If the surface were perfectly smooth (think about air-hockey

tables), you wouldn't need a skirt, you could just pump air under the

hovercraft and it would create a nice cushion. In practice most

surfaces are somewhat irregular, so the skirt needs to be flexible

enough to adapt to the surface, yet strong enough to hold in the air

pressure.

Figure 1: A foam circle cut out of the sheet of rigid foam.

For the base we will be using 1.5 inch rigid foam insulation. This is

a lightweight material that is easy to work with and relatively

inexpensive. There are a variety of circle templates that you can use

ranging from about 12 inches to 17 inches in diameter. You are free

to make your hovercraft whatever diameter you choose. The only

constraints are that it should be larger than 10 inches in diameter

and no more than 20 inches. You can also create other shapes,

although I suggest you cut a circle as it makes creating a good skirt

significantly easier.

To cut the foam, first lay your template circle on top of the foam.

Select a portion of the foam that will result in as little wasted foam

as possible. Trace a circle on the foam with a pen or marker. Remove

the template and then carefully cut the foam out using provided knife.

When using the knife extend the blade to a length slightly longer than

the width of the foam and then use the locking nut to lock the blade

in place. Make sure to keep the blade perpendicular the surface to

ensure a clean cut. Small sawing motions may be helpful. Note,

you should cut the foam over the plywood or off the edge of the

table so that you do not cut into the workbenches. Also, it may be

helpful to do a rough cut first (minimizing waste) so that you can

maneuver the piece of foam more easily.

Figure 1 shows the end result. Having a perfect

circle is not critical, but you should trim off any large errors. You

can always make a slightly smaller circle if you mess up the first

cut.

Question: What diameter hovercraft base did you decide to use? What was your reasoning?

Figure

Figure 2: A flexible walled skirt design. Air flows down into the skirt and inflates it. Most air remains inside and recirculates. A small amount of air leaks out and provides the air cushion (Image modified from original on wikipedia.org hovercraft entry).

The skirt is the most critical component of a hovercraft. There are

multiple types of skirts including bag skirts, wall skirts, and finger

skirts (roughly ranging from easiest to hardest to build). The goal

of all skirt designs is to provide a small cushion of air under the

hovercraft, while adapting and conforming to any irregularities in the

surface. If the surface were perfectly smooth (think about air-hockey

tables), you wouldn't need a skirt, you could just pump air under the

hovercraft and it would create a nice cushion. In practice most

surfaces are somewhat irregular, so the skirt needs to be flexible

enough to adapt to the surface, yet strong enough to hold in the air

pressure.

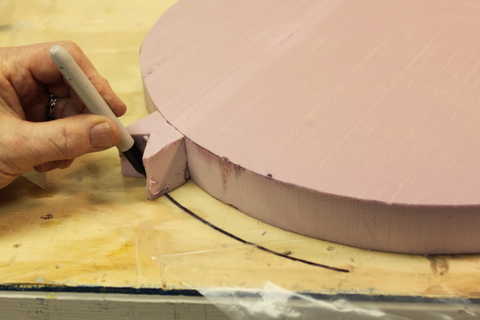

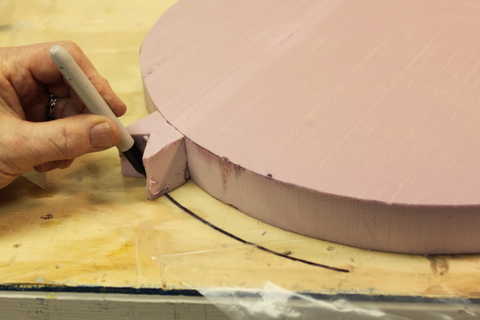

Figure 3: (left) Using a spacer to draw on the plastic. (right) Cutting the plastic.

A bag skirt is like putting an inner-tube under the hovercraft and

putting some holes in it on the bottom. Air flows out of the holes to

provide a cushion of air and the inner-tube conforms to the surface.

A wall skirt (the type we will be using, shown in

Figure 2) is basically a flexible wall going

around the hovercraft that keeps the air in and conforms to the

surface. A finger skirt consists of large number of small triangular

segments and is similar to the wall skirt except it is able to handle

a more varied terrain as each segment of the skirt is more flexible

and independent of the other segments.

To construct a wall skirt we will use 5mil plastic sheeting. Through

experimentation I found that this particular type and thickness

plastic resulted in a good skirt for this size hovercraft. Start by

laying the foam you cut on top of the plastic. Create a spacer out of

scrap foam to help you guide drawing a circle that is approximately

0.75 inches larger than foam circle as show in

Figure 3. Then cut out the plastic circle.

Figure 3: (left) Using a spacer to draw on the plastic. (right) Cutting the plastic.

A bag skirt is like putting an inner-tube under the hovercraft and

putting some holes in it on the bottom. Air flows out of the holes to

provide a cushion of air and the inner-tube conforms to the surface.

A wall skirt (the type we will be using, shown in

Figure 2) is basically a flexible wall going

around the hovercraft that keeps the air in and conforms to the

surface. A finger skirt consists of large number of small triangular

segments and is similar to the wall skirt except it is able to handle

a more varied terrain as each segment of the skirt is more flexible

and independent of the other segments.

To construct a wall skirt we will use 5mil plastic sheeting. Through

experimentation I found that this particular type and thickness

plastic resulted in a good skirt for this size hovercraft. Start by

laying the foam you cut on top of the plastic. Create a spacer out of

scrap foam to help you guide drawing a circle that is approximately

0.75 inches larger than foam circle as show in

Figure 3. Then cut out the plastic circle.

Figure 4: Taping the plastic disk to the hovercraft base.

The next step is to tape the plastic to the bottom of the hovercraft.

Place the foam over your plastic cutout and center it. Now, fold up

the plastic, it should come about half way up the edge of the foam.

As shown in Figure 4, tape the skirt all around

the hovercraft. The tape will extend slightly higher than the top of

the foam, fold this down all around. Assure that the tape is well

adhered to the foam all the way around. The plastic should now

completely cover the bottom of the hovercraft. When taping, the

plastic does not need to be completely tight to the base, but it

should have relatively even tightness all the way around.

Figure 4: Taping the plastic disk to the hovercraft base.

The next step is to tape the plastic to the bottom of the hovercraft.

Place the foam over your plastic cutout and center it. Now, fold up

the plastic, it should come about half way up the edge of the foam.

As shown in Figure 4, tape the skirt all around

the hovercraft. The tape will extend slightly higher than the top of

the foam, fold this down all around. Assure that the tape is well

adhered to the foam all the way around. The plastic should now

completely cover the bottom of the hovercraft. When taping, the

plastic does not need to be completely tight to the base, but it

should have relatively even tightness all the way around.

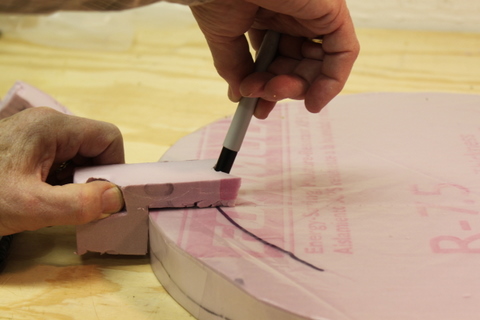

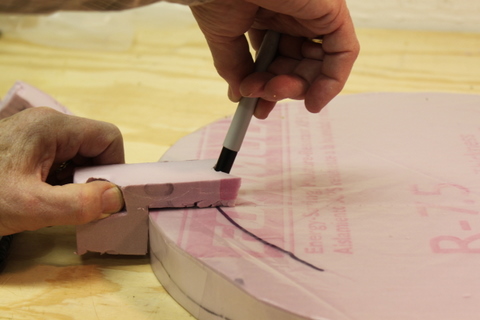

Figure 5: (left) Marking the inside of the plastic with a spacer. (right) Cutting the inside of the plastic to form the skirt.

The next step is to mark and cut a circle out of the center of the

skirt. This will leave a annulus of plastic around the edge of the

hovercraft, forming the skirt. Again, create a guide using left over

foam as shown in Figure 5. You should size it

such that there will be about 1.5 inches of plastic remaining. Then

cut out the inner circle. Try to cut smoothly, as this will be the

edge of the skirt. Figure 6 shows the resultant

skirt.

Figure 5: (left) Marking the inside of the plastic with a spacer. (right) Cutting the inside of the plastic to form the skirt.

The next step is to mark and cut a circle out of the center of the

skirt. This will leave a annulus of plastic around the edge of the

hovercraft, forming the skirt. Again, create a guide using left over

foam as shown in Figure 5. You should size it

such that there will be about 1.5 inches of plastic remaining. Then

cut out the inner circle. Try to cut smoothly, as this will be the

edge of the skirt. Figure 6 shows the resultant

skirt.

Figure 6: The resulting skirt.

Note that you may want to experiment with the efficiency of the skirt

and lift (described in Section 5) before

completing the final thruster layout in the next section. You will,

of course, have to install the lift thruster first.

Question: Describe the construction of the skirt and any problems you

encountered. Did your first skirt work as expected?

Figure 6: The resulting skirt.

Note that you may want to experiment with the efficiency of the skirt

and lift (described in Section 5) before

completing the final thruster layout in the next section. You will,

of course, have to install the lift thruster first.

Question: Describe the construction of the skirt and any problems you

encountered. Did your first skirt work as expected?

4.3 Thruster Layout

In this section we will come up with a layout for the thrusters. The

hoverboard supports a total of six thrusters. One will be used as the

lift thruster. The remaining five can be positioned in any

configuration.

4.3.1 Lift Thruster

Start by installing the lift thruster. To do so, find the center of

your hovercraft. Hold the small end of the thruster over the center

of the hovercraft. Trace this using a pen or marker and cut out the

foam. Note that the hole should be slightly small so that friction

will hold the thruster in the hole. It is best to start with a

smaller hole, as it is easier to make it larger later1. Slide the

small end of the thruster into the hole. At this point you should

probably verify that your skirt works properly by doing

Section 5.

4.3.2 Motion Thrusters

You have 5 remaining thrusters to use to control the hovercraft. The

layout of these is up to you. However, your hovercraft must be

omni-direction (must be able to translate in any direction without

needing to rotate first). In addition, you should have rotational

control. Note that the thrusters can only operate in one direction

(they can only push, not pull).

There are a couple of configurations you can use to achieve

omni-directional and rotational control. One idea is to have three

translational thrusters (120° separation) and two opposing

rotational thrusters. To move in some directions, you will have to

use multiple thrusters. You could also use four translational

thrusters (±x, ±y) and one rotational thruster. With this

configuration you may only be able to rotation in one direction

quickly, but you could potentially utilize the torque from the lift

thruster to rotate in the other direction. Finally, you could place

some of the translational thrusters at a slight angle so they would

exert a torque on the craft and produce a rotation. The choice is up

to you. It is easy to reconfigure the thrusters, so you can try a

variety of setups.

Question: What thruster configuration did you decide to use (a picture may be useful)? Why did you choose this?

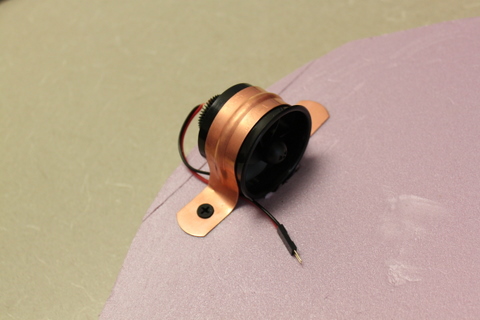

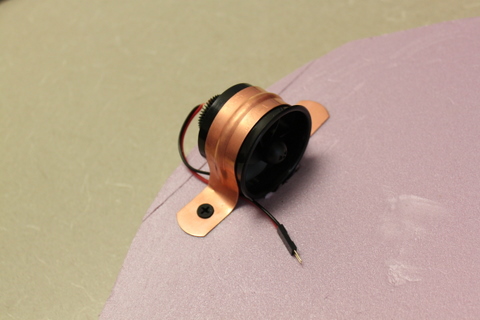

Figure 7: The mounted thruster.

To mount the thrusters we will use 1.5 inch copper pipe hangers and

screws as shown in Figure 7. These to not fit

exactly, however, you can pliers to form them to the thrusters. You

should make sure that they hold the thrusters tight against the

hovercraft, but that they do not deform the thruster housing as this

will impede the thruster. You can cut a small channel or press the

lip of the thruster into the foam to help lock it in place. Use the

1.25 inch drywall screws to secure the bracket. Do not tighten them

too much as the foam is soft and you will easily strip the hole.

Once you have soldered extension wires onto the thrusters (in the next

Section), you can bury the wires in the foam to keep them out of the

way. To do so, cut a small channel in the foam. Place the wires in

the channels and then tape over them to keep them inside.

Figure 7: The mounted thruster.

To mount the thrusters we will use 1.5 inch copper pipe hangers and

screws as shown in Figure 7. These to not fit

exactly, however, you can pliers to form them to the thrusters. You

should make sure that they hold the thrusters tight against the

hovercraft, but that they do not deform the thruster housing as this

will impede the thruster. You can cut a small channel or press the

lip of the thruster into the foam to help lock it in place. Use the

1.25 inch drywall screws to secure the bracket. Do not tighten them

too much as the foam is soft and you will easily strip the hole.

Once you have soldered extension wires onto the thrusters (in the next

Section), you can bury the wires in the foam to keep them out of the

way. To do so, cut a small channel in the foam. Place the wires in

the channels and then tape over them to keep them inside.

4.4 Soldering Thruster Wires

The wires on the thrusters are too short to reach a single location

where the hoverboard will be mounted. You will need to extend the

wires to reach a single location where the hoverboard will be mounted.

The hoverboard is 2 by 4 inches and the motor connectors are located

in one corner of the board. Pick a location for the hoverboard and

determine the rough length of the each of the wires needed to reach

this location.

Cut the existing thruster wires such that each end of the wires are at

least 1 inch long. We will use the existing connectors on the

thrusters and insert a segment of wire by soldering to make them

longer. Soldering is an important skill that always comes in useful

when working with embedded systems. In class you saw a demonstration

of how to solder wires. This is the basic technique that you will

use. All of the components on the hoverboards were soldered by hand

using similar techniques.

Now cut a segment of red and black wire from the spools that will be

long enough to enable the thrusters to reach the hoverboard location

(note that it is better to have it slightly too long versus too

short). Strip approximately a quarter inch of off of each end of all

wires. Now "tin" each of the ends of all the wires, as was

demonstrated in class. Tinning is the process of applying solder to

the wires.

Now place the tinned wire ends together, perhaps having someone else

hold them for you. Heat the wires and apply a little more solder so

that they are fully soldered together. Once you have soldered all the

joints, have someone else look at them and verify that the look well

soldered. Remember that there should be solder over all the wire,

there should be significant overlap of the wires, and the solder

should be smooth, without sharp points. Once someone else verifies

that the joints look good, use electrical tape to tape all of the

wires so that nothing is exposed.

It is said that robotics is the "science of cables and connectors."

Double check that all connections are good, otherwise you may run into

trouble later when a thruster stops working for an unknown reason. It

also may be a good idea to test each individual thruster before and

after adding the extension to verify that they function.

Everyone in your group should solder at least one thruster.

5 Hovercraft Experiments

Now that you have designed and assembled your hovercraft, it is time

to test how well it lifts. Note that you may find that you need to

redo your skirt if the performance is not very good. Typical problems

include loud vibrations, high friction, or air gushing out of one side

or another. Sometimes it is possible to fix these problems by adding

or removing weight from the hovercraft or adjusting the balance.

Question: Report on how well the skirt of your hovercraft works. Did

the first version work? If not, what were the problems and how did

you overcome them?

5.1 Powering Thrusters

Note, the thrusters are somewhat inexpensive and I have found

that they may die if run consecutively for longer than 10 minutes at

a time. Try to limit using the thrusters to times when you actually

need to use them. Do not leave them running if you are not actively

performing experiments. The symptoms you will see if you do run

them for too long are that the thrust output will decrease

significantly or it will stop completely. I suspect that this is

due to motor overheating, although it could be caused by other

problems (e.g. worn brushes). Let me know if any of your motors

fail and please try to describe the usage characteristics.

As we are not yet using the Hoverboard, we will be using a power

supply to power the thrusters. Before powering a thruster connected

to the hoverboard, we will power a thruster that is not connected to

anything. If you have already connected all of your thrusters,

temporarily remove one for these experiments.

The power supplies have a maximum current rating of 2.5A and go up to

30V. You should start by setting the voltage to 8.4V. This is near

the voltage of the batteries that we will be using later in the

course. A number of extension cables have been provided that enable

connecting the power supply to the thrusters. Without the thruster

connected to anything, locate one of the extension cables and plug the

red wire into the positive (+) terminal of the power supply and the

black wire into the negative (-) terminal. Most systems use red to

indicate positive voltage and black to indicate negative, however,

this is just a convention so do not rely on it.

Question: The thrusters have a rated power of about 41W at 8.4V. How

many Amps do they draw? The power supply cannot supply this much

power.

With the voltage set to 8.4V, set the current control nob to a middle

position. Have one person hold the casing of the thruster firmly,

keeping fingers away from the blades. Another person should then

connect the thruster to the power supply, red-to-red and

black-to-black. Note that there may be a small spark and the motor

will "jump" as it turns on.

Question: What is the voltage and current reading on the power supply?

How much power is the motor using?

Disconnect the thruster from the power supply. Repeat this experiment

with different (higher and lower) current limits.

Question: Record the voltage and current for a number of settings and

report this and the total power usage. What is the minimum current

that enables the motor to turn on?

Now, set the current limit the maximum and repeat these experiments by

varying the voltage from 0.0V to 8.4V.

Question: Report your findings for these experiments. Explain the

similarities or discrepancies from the initial experiment.

Question: Is all of the power converted into thrust? Where does the

rest go?

5.2 Lift Experiments

Now, instead of connecting the power supply to a thruster you are

holding, connect it to the main lift thruster. Start with a power

setting just slightly above the power needed to start the motor.

Slowly increase this until the hovercraft glides smoothly on your

workbench surface. Note that if you have problems (excessive

vibration, high friction, air venting, etc.), you may need to

redistribute the weight on your hovercraft, increase the weight, or

redo your skirt.

Question: How much power do you need to supply to the lift thruster to

create low friction hovering on your workbench? How about when it is

on the carpet or other surfaces?

There are pulleys, string, and weights (lots of nails that you can

measure with the scale, please put them back in their boxes when you

are done) in the lab. We will use these to characterize the forces

needed to move the hovercraft with different lift power and different

payload weights. Connect one end of the string to the hovercraft,

thread the other end through the pulley, and finally connect the other

end of the string to a weight. By holding the pulley at the edge of

the table, you can drop the weight and determine the minimum weight

needed to move the hovercraft. You can also time how long it takes to

move the hovercraft a fixed distance.

Question: Perform a number of trials to characterize the performance

of the hovercraft. Use different weights to pull the hovercraft,

different lift thrust levels, and try adding more weight to your

hovercraft (e.g. place a book on top of it without covering the lift

thruster). Which lift thrust level results in the least friction?

Does it continue to decrease when you increase the thrust, or does it

level off? Discuss the results of all of these experiments and

include any descriptive plots.

Question: (not required) Compute the friction of the hovercraft for

various thrust levels. Please show work and describe your reasoning.

Question: (not required) Repeat some of these experiments on different

surfaces.

5.3 Thrust Experiments

These experiments will require two power supplies. Use one to power

the lift thruster at a level of low friction and the other to power

one of your translational thrusters. Remember to disconnect the lift

thruster when you are not actively performing experiments. Also, do

not run it for longer than 10 minutes at a time without a few minute

break. This will help to prevent damage to the thrusters.

In these experiments we will continue to use the rope, pulley, and

weights, but now we will use them to characterize the translational

thrusters. Start with the weight near the ground and the hovercraft

near the pulley with the rope connected near the translational

thruster you will be testing. Now engage the thruster.

Question: How much weight can the thruster lift? What about at

different thruster power levels? Convert this into a thrust force,

assuming zero friction, by determining the maximum weight that the

hovercraft can move and recall F=ma and on earth a=g=9.81m/s2.

Now we will characterize the rotational speed of your hovercraft.

Time how long it takes to rotate a full rotation clockwise and

counterclockwise. For accurate results you may want to repeat this

several times and/or count how long it takes to achieve multiple

rotations.

Question: Report and analyze the results of your rotational

experiments at different thrust levels.

Question: Does the hovercraft translate when you do this? If so, do

you think it will be possible to compensate for this using the

translational thrusters?

Question: Is the rotational speed constant? Or does it increase over

time? Is there a maximum rotational speed? Does it achieve this

quickly or slowly. For example, is the rotational speed just as fast

in the first quarter turn as it is in the last quarter turn?

Question: Does the rotational speed change on different surfaces?

6 To Hand In

You should designate one person from your group as the point person

for this lab (each person needs to do this at least once over the

semester). This person is responsible for organizing and handing in

the report, but everyone must contribute to writing the text. You

should list all group members and indicate who was the point person on

this lab. Your lab should be submitted by email before the start of

class on the due date. A pdf formatted document is preferred.

Your lab report should have an introduction and conclusion and address

the various questions (highlighted as Question: ) throughout the lab in

detail. It should be well written and have a logical flow. Including

pictures, charts, and graphs may be useful in explaining the results.

There is no set page limit, but you should make sure to answer

questions in detail and explain how you arrived at your decisions.

You are also welcome to add additional insights and material to the

lab beyond answering the required questions.

N.B. This is part (a) of Lab 1. You should complete a single

lab report for all of Lab 1. However, you should start writing your

lab report now, do not wait until you have completed all of the lab.

Question: You should make sure to include a picture of your final hovercraft.

Question: Robots like to have names, what are you going to call your hovercraft?

Question: For everyone in your group how many hours did each person spend on this part and the lab in total? Did you divide the work, if so how? Work on everything together?

Question: Please discuss and highlight any areas of this lab that you

found unclear or difficult.

7 Appendix: Material Availability

Most materials (foam, brackets, screws, etc.) are available at any

hardware store. The 5mil plastic, used for the skirt, is available in

a number of places, however, I found that the 5mil plastic available

at Ace Hardware on rolls (cut to length, intended for covering

windows) is the right thickness and flexibility for the skirt. Other

plastics tended to vibrate. I am not sure the exact type of plastic

(as it was not labeled in the store), but I have found it in a number

of Ace Hardware stores in a variety of states.

The thrusters (ducted fan EDF40) were purchased online at

towerhobbies.com and are part number GWSG4000 or L5HHN906. They may

be available other places and there are certainly other ducted fans

that work well. A good alternative for a lift motor is an air

mattress pump, although most are larger than the ducted fans. The

same hovercraft design can be enlarged fairly easily to carry a person

in which case a leaf blower works well as a lift pump (and thicker

skirt plastic may be needed).

Footnotes:

1If you

do happen to make it too large, you can create another hole in a

different location as the lift thruster does not need to be exactly

in the center. Cover over your old hole with tape

File translated from

TEX

by

TTH,

version 3.89.

On 21 Jan 2011, 11:39.